Using Damascus steel for knife making involves carefully selecting the right billet to achieve desired blade characteristics.

This is followed by forging and heat treating. Each step enhances the knife’s performance and aesthetic appeal.

The unique composition and pattern variations of Damascus steel offer a challenge and opportunity for skilled artisans to blend tradition with innovation.

Key Takeaways

How to Use Damascus Steel for Knife Making

- Select Damascus billets based on the desired pattern and performance.

- Apply forging techniques to create unique blade patterns.

- Master the heat treatment process for optimal hardness and edge retention.

- Utilize specialized tools like belt grinders for precision.

- Maintain knives through regular sharpening and proper care to ensure longevity.

What are the different types of Damascus steel, and how do their properties affect knife performance?

Traditional Damascus, such as Wootz, features intricate patterns and exceptional strength.

Pattern Welded Damascus combines different steels to achieve a balance between hardness and flexibility.

Stainless Damascus, on the other hand, provides excellent corrosion resistance.

Traditional Damascus (Wootz)

Wootz steel, also known as Essential Damascus steel, includes various types with distinct properties affecting knife performance, such as carbon content and stainless characteristics. Originating from ancient methods in India and the Middle East, Wootz steel is famous for its unique watery or flowing patterns.

The carbon content in traditional Damascus steel plays a crucial role in its hardness, edge retention, and overall durability. Blades with higher carbon content are usually harder and can maintain a sharper edge, although they may be more susceptible to corrosion.

Conversely, some variations of Wootz steel exhibit stainless properties that enhance resistance to rust and staining, prolonging the knife’s lifespan. Balancing carbon content and stainless features is essential when choosing the right type of traditional Damascus steel to meet your cutting needs and maintenance preferences.

Pattern Welded Damascus

Pattern Welded Damascus steel for knife making involves layering different steels with varying carbon content and forge-welding them together, resulting in a blade with a unique pattern. This process combines steels to enhance the blade’s strength and flexibility.

The choice of steels impacts the knife’s performance, with higher carbon content steels providing better edge retention and sharpness for precise cutting tasks, while stainless steels offer improved corrosion resistance, making them suitable for wet or humid environments.

Stainless Damascus

Stainless Damascus steel stands out in knife making due to its blend of aesthetics and functionality. It excels in:

- Corrosion Resistance: Stainless Damascus steel resists rust and corrosion, making it perfect for environments with moisture and acids.

- Aesthetic Appeal: Retaining the striking patterns of traditional Damascus steel, it enhances the blade’s visual appeal.

- Durability: Known for its longevity and minimal upkeep, Stainless Damascus steel ensures a lasting knife.

- Versatility: Ideal for high-end culinary knives, it maintains a sharp edge and withstands frequent use.

- Application: Popular in crafting decorative and collector’s knives, adding elegance to the final product.

Carbon Steel vs. Stainless Damascus

When it comes to choosing between carbon steel and stainless Damascus, your decision will significantly impact your knife’s performance, affecting factors like edge retention and corrosion resistance.

Carbon steel Damascus, such as 1084 and 15N20, is a popular choice among custom knifemakers. These steels, with comparable carbon levels, may differ in alloy components like nickel, which can enhance the contrast in the etched pattern.

Conversely, stainless steel Damascus offers superior corrosion resistance but can present challenges in forge welding due to its higher alloy content. Combinations like CruForgeV/15N20 and 1.2419/15N20 have undergone specific tests to assess their edge retention and overall functionality.

When choosing between carbon and stainless Damascus, consider your priorities – if you value edge retention and are willing to conduct maintenance to prevent corrosion, carbon steel may be the optimal selection. However, if corrosion resistance is a top priority for you and you’re prepared to tackle the complexities of forge welding, stainless steel Damascus could be the more suitable option.

Where can I acquire Damascus steel billets, and how do I choose the right one for my project?

When looking for Damascus steel billets for your knife making project, it’s important to consider factors such as the size, pattern, and core steel types. These aspects will greatly impact the final appearance, performance, and strength of your knife.

To select the appropriate billet for your project, ensure that it meets your specific requirements and preferences.

Size

Selecting the right size of your Damascus steel billet is crucial for your knife making project. Larger billets are best for crafting chef’s knives and other big blades, while smaller billets are more suitable for utility and paring knives.

Make sure to match the billet size with your intended knife design and consider the blade length as well. Some suppliers offer custom-sized billets for unique knife projects, allowing you to tailor the size to your specific needs.

Pattern

How to Choose Damascus Steel Billets for Knife Making

When looking for Damascus steel billets for your knife making project, consider exploring online suppliers that offer various patterns to match your aesthetic preferences and knife design needs.

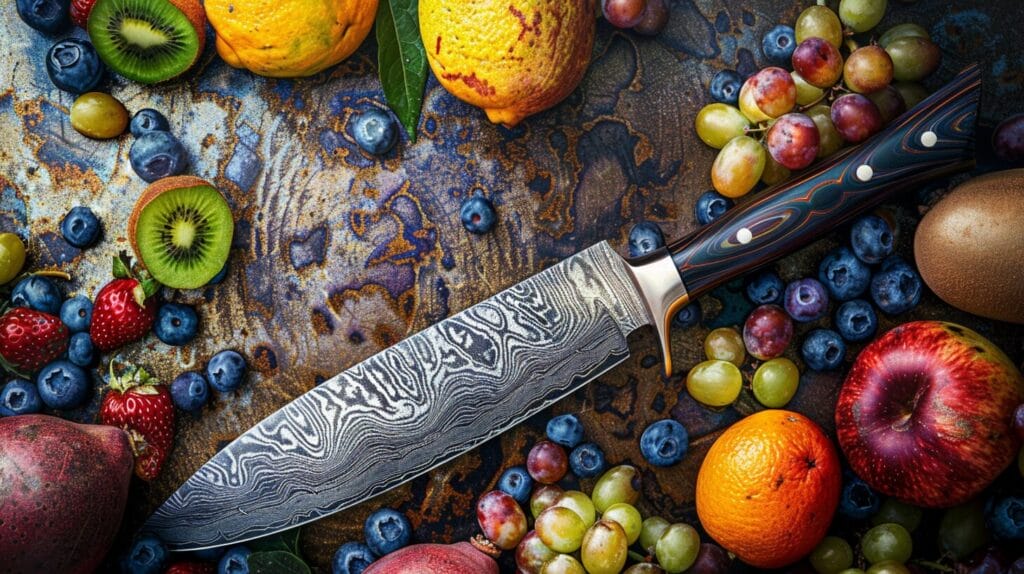

Damascus steel presents a diverse range of patterns, from graceful waves to intricate mosaics. When selecting a pattern, think about how it will complement your knife’s overall design.

Seek out suppliers that provide detailed images of the available patterns, enabling you to visualize how they’ll look on your completed knife. Also, take into consideration the billet’s size in relation to the knife you intend to create to ensure the pattern is showcased effectively.

Core Steel Types

When you’re looking to acquire Damascus steel billets for your knife making project, it’s crucial to consider factors like size, pattern, and core steel types to ensure your knife performs well and looks stunning.

Here are some tips for selecting the right core steel types for your Damascus billet:

- Opt for high-carbon steels like 1095 for superior hardness and edge retention, perfect for enhancing the cutting performance of your knife.

- Consider stainless steels such as 15N20 for excellent corrosion resistance, ensuring your knife stays durable and rust-free.

- Mix different steel types in your billet to create visually striking patterns in the blade and improve the overall properties of the knife.

- Choose a combination of steel types that complement each other’s strengths to achieve a balance of performance and aesthetics in your final knife.

- Feel free to experiment with various core steel types to discover unique patterns and properties in your Damascus steel knife.

Hardness

Looking for Damascus steel billets for your knife making project? Prioritize reputable suppliers to ensure the hardness and quality of the steel meet your needs. Authentic Damascus steel typically has a hardness rating between 58 and 62 on the Rockwell C scale, indicating high quality with a balance of strength, durability, and edge retention. By getting your Damascus steel billets from trusted sources, you can be confident they meet your project’s standards.

Consider the size, pattern, and core steel types when choosing a Damascus steel billet. Select a billet that fits your knife design’s size requirements and has a visually appealing pattern that matches your preferences. Also, pay attention to the core steel types used, as they can impact the knife’s overall performance and characteristics. By evaluating these factors carefully, you can craft a top-notch knife that meets your expectations.

How does working with Damascus steel differ from using regular knife steel?

Working with Damascus steel differs from using regular knife steel due to the need for balancing preserving unique patterns and maintaining blade integrity during forging.

Heat treatment is crucial as Damascus steel can be more sensitive to temperature changes than regular knife steel.

Challenges may arise in achieving consistent hardness and avoiding delamination while crafting with Damascus steel.

Forging Techniques

Forging techniques for Damascus steel require a complex process of layering and folding different types of steel to create a unique pattern and properties for the blade.

Here’s what to expect when working with Damascus steel:

- Each fold and weld contributes to the distinctive wavy or mottled pattern on the blade’s surface.

- The layered steel is forged into the desired shape, showcasing the intricate layers within the blade.

- The repeated folding and welding process results in a billet with hundreds or even thousands of layers, enhancing the blade’s strength and durability.

- Alternating between high-carbon and low-carbon steels during forge welding creates a blade with a balance of hardness and flexibility.

- The final forged shape of the Damascus steel blade reflects the craftsmanship and artistry involved in the forging process, making each blade unique and visually striking.

Heat Treatment

When working with Damascus steel, the intricate heat treatment process is crucial to enhancing its unique properties. This process involves heating the blade to high temperatures and then quenching it in oil or water.

The balance of hardness, toughness, and edge retention in the blade is determined by this critical heat treatment process. Mastering the nuances of heat treatment is essential for creating effective and long-lasting Damascus steel knives.

Potential Challenges

Mastering the art of working with Damascus steel involves overcoming unique challenges compared to regular knife steel, requiring specific skills and expertise in welding, heat treatment, and maintenance.

- Welding layers of steel together demands precision to ensure a strong, consistent bond.

- The varying carbon content in Damascus steel complicates the heat treatment process, as different layers may react differently to the same treatment.

- Proper care is crucial due to Damascus steel’s higher susceptibility to corrosion compared to certain stainless steel alloys.

- The forging process is labor-intensive, involving multiple folding and welding steps to achieve the desired pattern and layer count.

- Maintaining Damascus steel knives involves regular upkeep to prevent rust and pitting, ensuring their longevity and performance.

What special tools or techniques are required for shaping and sharpening Damascus knives?

Special tools and techniques are necessary for shaping and sharpening Damascus knives due to their layered structure.

Tools such as a belt grinder or power hammer are essential for working with the unique layers. Proper heat treatment is crucial to ensure the layers bond correctly and form a durable blade.

Moreover, specific sharpening and polishing techniques are required to enhance the intricate patterns of the Damascus steel while maintaining its sharp edge.

Forging and Grinding

To shape and sharpen Damascus knives effectively, it’s crucial to utilize special tools like an angle grinder with a coarse grit belt. This tool helps in carefully grinding the blade without overheating the steel due to its layered structure.

When forging and grinding Damascus knives, maintaining the integrity of the layers is paramount. Here are some essential points to consider:

- Apply gentle pressure: When grinding, use a light touch to prevent the layers from separating.

- Take your time: Work slowly to ensure an even grind across the entire blade surface.

- Allow for cooling breaks: Pause regularly to let the steel cool down and prevent overheating.

- Frequent inspections: Check the blade regularly for any signs of overheating or damage during the grinding process.

- Be patient: Achieving the desired shape and sharpness may require time, so practice patience and be meticulous in your approach.

Heat Treatment

To properly shape and sharpen Damascus knives, specialized tools and methods are necessary to accommodate the layered structure and ensure effective heat treatment.

A crucial tool for this process is a heat treating oven with temperature control, which is used to heat the steel to the precise level required for hardening.

Additionally, a quenching tank filled with either oil or water is indispensable for quickly cooling the blade after heating, solidifying its hardened state.

Given the layered composition of Damascus steel, meticulous attention must be paid during heat treatment to ensure that each layer responds uniformly to the heat, resulting in a blade with consistent hardness throughout.

Effective heat treatment not only strengthens the blade but also boosts its durability by minimizing the risk of chipping or cracking.

Sharpening

Damascus knives require specialized tools and techniques for sharpening due to their layered structure. To maintain their intricate patterns and sharpness, follow these steps when sharpening your Damascus knife:

- Start with a high-quality sharpening stone or whetstone to keep the blade sharp.

- Begin with a coarse grit stone to eliminate any dullness or nicks.

- Progress to finer grit stones gradually to refine the edge and improve sharpness.

- Maintain a consistent angle while sharpening to ensure the edge is aligned evenly.

- Apply even pressure along the whole length of the blade to prevent uneven edges.

Polishing

When working on shaping and sharpening Damascus knives, it’s essential to use specialized tools and techniques to achieve optimal results. Once the sharpening process is complete, polishing the blade is crucial to bring out the striking beauty of the Damascus pattern.

To achieve a glossy finish, utilize a leather strop or fine-grit sandpaper. A leather strop, a piece of leather used for polishing, is employed by moving it back and forth along the blade’s edge. Start by applying a polishing compound on the strop, then proceed to draw the blade across it at a consistent angle. This method aids in refining the edge and showcasing the intricate patterns of the Damascus steel.

Alternatively, fine-grit sandpaper can also be utilized in a similar fashion for polishing. Remember to maintain a steady hand and use uniform strokes to achieve a consistent finish. The final step of polishing the blade not only enhances its visual appeal but also elevates the overall quality of the Damascus knife.

Maintenance

When maintaining Damascus knives, it’s crucial to use the right tools and techniques to preserve their unique composition. Here are some important considerations:

- Diamond-Coated Sharpener: Opt for a diamond sharpening stone as it’s best suited for the hardness of Damascus knives and can effectively sharpen the different steel layers.

- Consistent Sharpening Angle: Ensure you maintain a steady angle while sharpening to keep all layers uniformly sharp and symmetrical.

- Gentle Pressure: Apply light pressure during sharpening to avoid uneven wear on the various steel layers of the knife.

- Prevent Overheating: To prevent damage to the delicate layers of Damascus steel, use water or oil as a lubricant while sharpening to keep the blade cool.

- Regular Honing: Make it a habit to regularly hone your Damascus knife with a ceramic or diamond honing rod to maintain its sharpness by realigning the microscopic teeth between sharpenings.

How can I achieve the desired finish and bring out the unique patterns in my Damascus blade?

To achieve the desired finish and emphasize the unique patterns in your Damascus blade, you can start by wet sanding the surface to obtain a smooth finish.

Next, buffing the blade will help highlight the intricate layers of steel.

In addition, applying an etching or creating a forced patina can further enhance the visual characteristics of your Damascus knife.

Wet Sanding

When wet sanding Damascus blades, it’s crucial to follow a systematic approach to achieve the desired finish and bring out the unique patterns. Start by using a coarse grit sandpaper (around 400-600 grit) and gradually progress to finer grits (1000-2000 grit), utilizing water as a lubricant.

Apply consistent pressure while maintaining a steady angle to avoid creating uneven scratches. This method will help to slowly remove imperfections and smooth the surface of the blade, enhancing its visual appeal.

Remember these key steps for successful wet sanding of your Damascus steel blade:

- Begin with a coarse grit sandpaper and work your way up to finer grits.

- Use water as a lubricant to facilitate the sanding process.

- Apply uniform pressure to ensure a consistent finish.

- Maintain a steady angle to prevent uneven scratches.

- Follow a systematic approach to gradually enhance the visual characteristics of the blade.

Buffing

To enhance the appearance of your Damascus blade, consider using a buffing wheel or cloth after wet sanding. Apply a polishing compound like Maas Metal Polish or Flitz Metal Polish to emphasize the unique patterns in Damascus steel.

After wet sanding, put a small amount of polishing compound on the buffing wheel or cloth. Press the blade against the spinning wheel gently, ensuring it stays cool. Move the blade back and forth across the wheel to bring out the intricate patterns.

This careful buffing process will create a mirror-like finish, showcasing the beauty of Damascus steel. Take your time and pay attention to detail during buffing for the best results.

Etching

Etching is a process that can enhance the unique patterns in your Damascus blade.

Follow these steps to achieve the desired finish:

- Prepare the etching solution: Combine equal parts of ferric chloride and water in a container.

- Submerge the blade: Gently place the blade into the etching solution, ensuring it’s fully covered.

- Monitor the process: Let the blade sit in the solution for a few minutes, checking its progress regularly.

- Rinse the blade: Once you achieve the desired pattern, take out the blade and rinse it thoroughly with water to stop the etching.

- Dry and inspect: Dry the blade and carefully examine the pattern to ensure it meets your expectations before moving on to the next steps in your knife-making process.

Forced Patina

To highlight the unique patterns in your Damascus blade, consider using polishing methods or creating a forced patina.

By applying chemical solutions like liver of sulfur or ferric chloride onto the blade, you can achieve a dark and even patina that not only adds protection but also brings out the intricate Damascus pattern.

Through careful application and experimentation with different techniques and concentrations, you can customize the appearance of your blade to your liking.

Frequently Asked Questions

Can I Create My Own Damascus Steel at Home for Knife Making?

Yes, you can make your own damascus steel at home for crafting knives by combining different types of steel, heating them, and forge-welding them together. This process demands skill, appropriate equipment, and safety measures.

What Are the Best Practices for Maintaining a Damascus Steel Knife?

To keep your Damascus steel knife in top condition, ensure it is dry after each use, avoid using harsh chemicals, and regularly oil the blade. Clean it with a soft cloth and store it in a dry place. Treating it well is key to maintaining its sharpness over time.

Are There Specific Safety Precautions to Consider When Working With Damascus Steel?

When handling damascus steel, it is important to wear appropriate eye protection, gloves, and a mask to prevent inhaling particles. Exercise caution when using power tools, ensure workspaces are kept clean to avoid tripping hazards, and handle hot metals with care.

Can Damascus Steel Knives Be Used for Everyday Cooking Tasks?

Yes, Damascus steel knives are suitable for everyday cooking tasks. They are valued for their durability, sharpness, and distinctive appearance, making them a great choice for daily use in the kitchen. Just remember to take proper care of them to maintain their quality.

How Can I Customize the Pattern and Design of My Damascus Steel Knife?

To personalize the design and pattern of your damascus steel knife, you can experiment with varying layering techniques and materials. By trying out different combinations of steel types, you can achieve unique and distinctive patterns for your knife.

Conclusion

Once you have grasped the fundamentals of working with Damascus steel for crafting knives, you can confidently choose the appropriate billet, forge the blade, and carry out the heat treatment process.

Remember to appreciate the distinctive patterns and characteristics of Damascus steel. With dedication and practice, you can produce exceptional knives that are both visually striking and highly functional.

Enjoy your crafting journey!